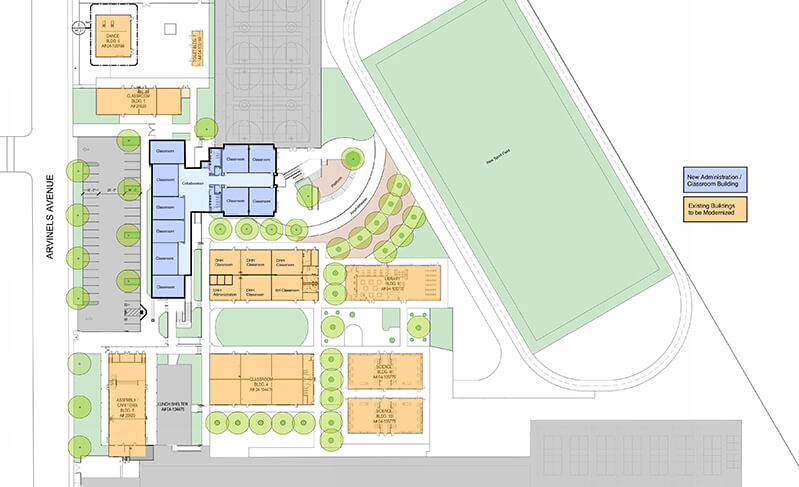

Innovation Middle School

Mechanical and plumbing design for Innovation Middle School. All existing portable buildings were replaced with a new 36,000 SF 2-story classroom building that includes new PE locker facilities, administration/counseling areas and student services. Existing permanent buildings were modernized with up-graded building systems for electrical, lighting, security, life safety, and air conditioning.

Mechanical systems include high efficiency rooftop packaged variable air volume (VAV) air handling units with heating hot water reheat for dehumidification and morning warm up and high efficiency rooftop packaged DX units with gas heating. All rooftop equipment is equipped with economizers to take advantage of the temperate climate. Zonal control is provided through VAV boxes with reheat coils. High efficiency heating hot water boilers provide heating throughout the buildings. Building exhaust systems were added as required to serve restrooms as well as to maintain building pressurization. Careful consideration was given to the controls of each system working closely with the district to provide alarm and monitoring as requested. With primarily east/west exposures the mechanical system was optimized to minimize peak loads.

Plumbing utilities were provided to each building as required. Each building is provided with natural gas pressure regulator and earthquake valve. Existing site natural gas mains required alterations to allow space for building construction. Each building is provided with roof drains and connected to site storm drainage system. High-efficiency, natural-gas fired water heaters provide domestic hot water to plumbing fixtures. A recirculation pump is provided to maintain hot water temperature to plumbing fixtures. High-efficiency, low flow plumbing fixtures are provided to reduce domestic water consumption.

Sustainable features include high efficiency boilers, variable speed pumps, variable air volume design, and high efficiency cooling units. Energy savings were increased with the addition of an economizer cycle that included gear driven dampers to minimize failures of linkage based economizer controls. A campus wide energy management system was also introduced to monitor and reduce energy use and allow control from the district central network.